Introduction

Nicotinamide Mononucleotide (NMN) has gained significant attention in the health and wellness industry, especially for its potential anti-aging properties. As a precursor to NAD+ (Nicotinamide Adenine Dinucleotide), NMN plays a critical role in cellular energy production, DNA repair, and metabolic regulation. Its increasing demand globally presents both opportunities and challenges for wholesalers and traders looking to enter or expand in the market.

In this comprehensive guide, we will explore everything wholesalers need to know about NMN, including its quality standards, production process, forms of supplementation, and storage methods. Understanding these aspects will help you make informed decisions when sourcing NMN products and building long-term relationships with reliable suppliers.

What is NMN and How Does it Work?

NMN is a natural compound that is produced in the body from three amino acids—glutamine, glycine, and cysteine. It is directly involved in the synthesis of NAD+, a coenzyme crucial for various biological processes, including energy metabolism, DNA repair, and regulation of aging. As people age, NAD+ levels decline, which can negatively affect overall health.

By supplementing with NMN, individuals can potentially boost their NAD+ levels, thereby supporting cellular health, enhancing metabolic function, and promoting overall wellness. This makes NMN a highly sought-after product in the global market, particularly among consumers seeking anti-aging and longevity solutions.

NMN Quality Control

Ensuring the quality of NMN is critical to meeting market demands and maintaining customer satisfaction. As a wholesaler, understanding how to evaluate the quality of NMN products is essential. Below are the key quality aspects to consider:

Purity and Source

The purity of NMN is crucial for its effectiveness. High-quality NMN should have a purity level of at least 98%. Wholesalers should verify the source of the raw materials used to produce NMN, ensuring they come from reliable and reputable suppliers.

Production Standards

It’s important to source NMN from manufacturers who adhere to recognized production standards such as Good Manufacturing Practices (GMP) and ISO certification. These certifications ensure that the manufacturing process is monitored and controlled to maintain high product quality.

Third-Party Testing

Wholesalers should always request third-party laboratory test results to verify the product’s purity, potency, and safety. These reports ensure that the NMN meets the necessary specifications and quality standards.

To learn more about evaluating NMN product quality, refer to our article on How to Evaluate NMN Quality: A Wholesaler’s Guide.

Detailed NMN Production Process

Understanding the production process is crucial for ensuring the quality and consistency of NMN products. Below is an overview of the key stages in the production of NMN:

From Raw Material to Finished Product

- Fermentation and Purification: NMN is typically produced through fermentation, a process that converts natural precursors into NMN. The fermentation is followed by a purification process to ensure that the final product is free of impurities and has the desired potency.

- Concentration and Drying: Once purified, the NMN is concentrated and dried to create either a powder or liquid form, depending on the product’s intended use.

Quality Control During Production

Throughout the production process, stringent quality control measures must be implemented. This includes testing for contaminants such as heavy metals, bacteria, and fungi. Regular checks ensure the final product meets safety and quality standards.

For more details on the NMN production process, check out our article on NMN’s Production Process: Key Steps Every Wholesaler Must Know.

Different Forms of NMN Supplements

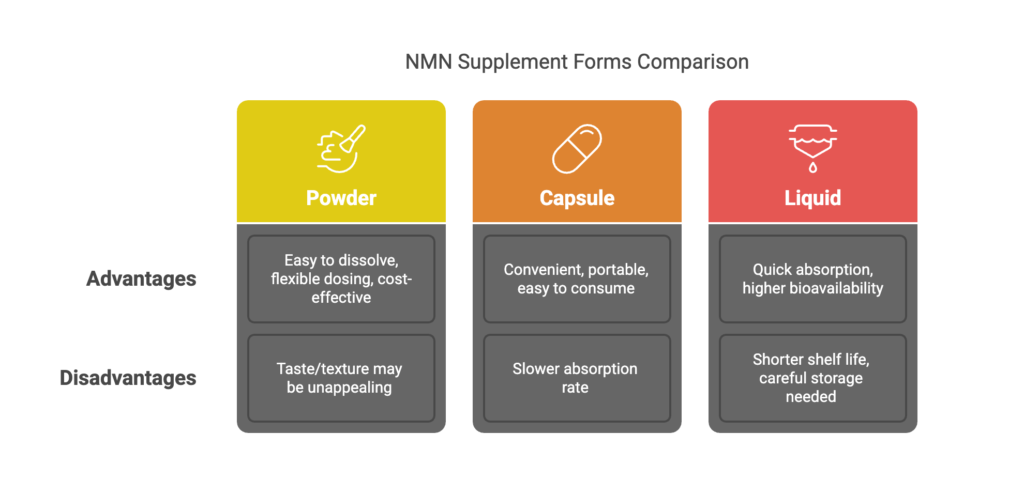

NMN supplements are available in various forms, each offering unique benefits and challenges. Wholesalers need to understand the differences between these forms to make informed purchasing decisions.

Powder Form

- Advantages: Easy to dissolve, flexible dosing, and cost-effective.

- Disadvantages: Not always preferred by consumers who dislike the taste or texture of powders.

Capsule Form

- Advantages: Convenient, portable, and easy to consume without measuring.

- Disadvantages: May have a slower absorption rate compared to other forms.

Liquid Form

- Advantages: Quick absorption, higher bioavailability.

- Disadvantages: Shorter shelf life and may require more careful storage conditions.

Understanding the pros and cons of each form helps wholesalers decide which NMN supplements to offer based on their target market’s preferences.

To learn more about choosing the right NMN form, refer to our article on NMN Solubility and Absorption: Choosing the Right Supplement Form.

Storage and Transportation of NMN

Proper storage and transportation are critical to maintaining the quality of NMN products. Environmental factors such as temperature, humidity, and light exposure can significantly impact the stability of NMN.

Ideal Storage Conditions

NMN should be stored in a cool, dry place away from direct sunlight. Avoid exposure to extreme temperatures and high humidity, as these can degrade the product’s potency.

Handling During Transport

During transportation, ensure that the NMN is kept at appropriate temperatures and protected from moisture and light. Packaging should be secure to prevent any physical damage to the product.

For more on storage and handling, see our article on How to Store NMN: Ensuring Optimal Quality Over Time.

Conclusion

For wholesalers and traders in the NMN market, understanding the product’s quality, production process, supplement forms, and storage requirements is essential to making informed sourcing decisions. By ensuring that you partner with suppliers who adhere to high-quality standards and transparent production processes, you can confidently provide your customers with a premium NMN product.

This guide serves as a comprehensive resource to help wholesalers navigate the complexities of the NMN market. By paying close attention to these factors, you will be better positioned to succeed in the growing NMN industry.